Motorola index

Back to Home

By Robert W. Meister WA1MIK

|

Maxtrac Index Motorola index Back to Home |

Hang-Up Mechanisms Used By Motorola Hand Microphones By Robert W. Meister WA1MIK |

|

There are several different microphone hang-up mechanisms used by Motorola hand microphones for the MaxTrac, Radius, GM300, and GTX (and similar) radios. They all eventually end up grounding the hang-up signal on the plug at the end of the cord to activate the tone-coded squelch feature of the radio. (The hang-up signal is often called the Monitor signal.) In the United States, the Federal Communications Commission (FCC) requires commercial radio users to listen and wait for inactivity on the channel before transmitting; one way to do this is to put the receiver into carrier squelch when the microphone is lifted from its resting position, usually in a hang-up clip of some kind.

In the descriptions below, tone-coded squelch refers to sub-audible tone (Continuous Tone Coded Squelch System - CTCSS) as well as low-speed digital (Digital Coded Squelch - DCS). When any of these microphones are removed from their hang-up clips, the receivers usually go into carrier squelch mode.

Other manufacturers tended to utilize one of these existing schemes.

Some Microphone History:

Back in the good old days, carbon-button microphone elements (the same as used by most telephones) were used by mobile radios. (Very early radios used an actual phone handset.) These required some source of filtered DC to work. That DC is still supplied by most Motorola mobile radios today, but it powers a preamp now. The hand mikes were made of cast-metal and the hang-up button was part of that casting. Tone-coded squelch came into widespread use in the 1960s as frequency sharing increased, and spurned the requirement for listening before transmitting. Users hardly ever flipped the tone On/Off switch on the radio's control head (it was too far away), so Motorola came out with the hang-up box in the late 1960s and early 1970s to force some compliance. Around this time the carbon mike element was being replaced by a dynamic one with a transistorized preamp inside the microphone element case. The electrically-active hang-up button was a 1980s feature but it took time to gain wide acceptance.

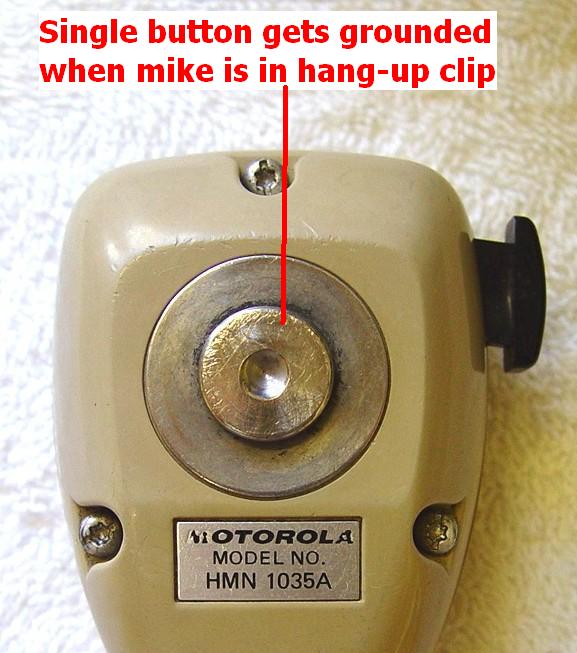

Single Button:

The cast metal case was pretty heavy, and all the radio manufacturers switched to plastic cased microphones in the late 1950s and early 1960s. The metal hangup button remained for durability, but was not made electrically active until much later (after the MICOR era). When it was, the point in the circuitry that used to be wired to the hangup box was connected to a new wire in the microphone cord, and connected to the metal hangup button on the back of the microphone case. Grounding this button enables the receiver's tone-coded squelch, if the radio has been programmed for it. You can ground the button to the radio chassis or any grounded piece of metal in your vehicle. The photo below shows a full-size hand mike.

When the microphone is placed into a grounded hang-up clip, the circuit is completed. If the clip will be mounted on an ungrounded surface, a ground wire needs to be attached to it. Here's a typical (well-used and pitted) metal hang-up clip:

The springy V-shaped piece in the middle presses against the hang-up button on the back of the microphone. The little dimple in the center fits into the depression in the hang-up button and helps hold the microphone in place.

Here's an official Motorola hang-up clip that's supplied with many mobile radios. Two sheet-metal screws (not shown) are also in the bag. Some kits contain instructions and crimp lugs for adding the optional ground wire:

Not all single-button microphones had an electrically-active button. There were older metal microphone cases in which the hang-up button was only used to support the mike in a U-shaped clip. Many of these were used with carrier-squelch radios. Disabling tone-coded squelch was done with a microphone hang-up box (described below).

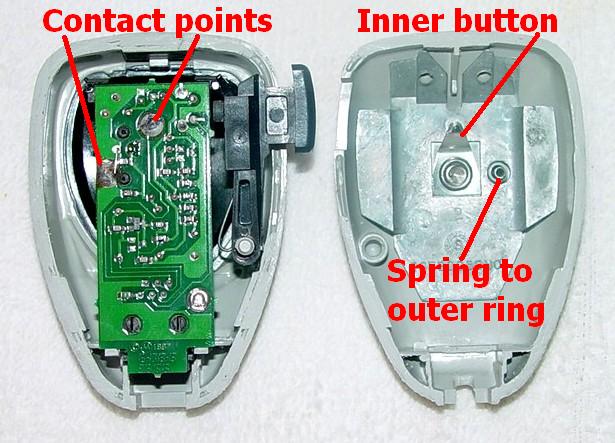

Concentric-Ring Button:

The same insulated metallic hang-up button is present on this microphone as well, but the larger metal plate/ring behind it is insulated from the center button and is connected to ground inside the microphone. You can either ground the center button to a grounded hang-up clip, or just place the hang-up button in an insulated metal hang-up clip, which will complete the circuit. This lets you use a grounded or ungrounded hang-up clip as long as some of it is made of metal. This is the back of a small palm mike commonly used with MaxTrac radios.

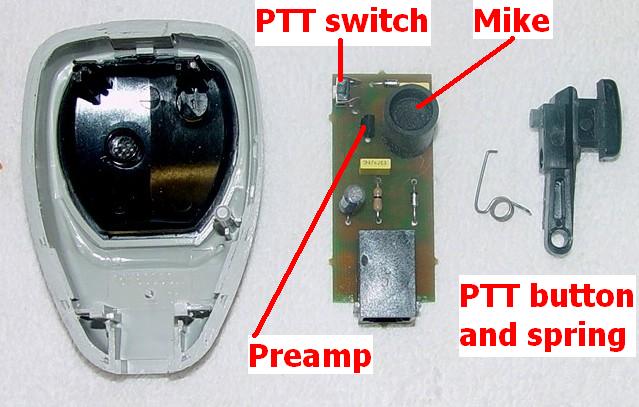

These palm mikes are hermetically sealed and are not serviceable except for replacing the modular cord. I had one with a defective PTT switch, so with nothing to lose, I decided to open it up. I used an X-ACTO razor saw, pictured below:

It took about half an hour to cut at the case joint (100% of the perimeter is glued or heat welded) as I didn't know what I would encounter inside. I managed to pry the case apart. The back with the hang-up button is one half, the front with the electronics, PTT button, and spring, are on the other half. Here's a photo of the insides:

I removed the PTT button, spring, and electronics and spread them out. This is all there is to this microphone:

I'm hoping to glue the case back together again after replacing the PTT switch. It'll never look as good as new, but it will work fine as a test mike.

I found the following dialog on one of the Yahoo! Groups as a response to a question about opening an HMN1056D microphone to repair it:

Try putting it in the freezer overnight. The next day, give it a couple of taps on the seam; most of the time it will pop open very easily. I've had success doing this on many battery packs and microphones.

Another person reported great success with this method:

Instead of putting the mike in the freezer, I used a can of freeze spray I had on hand for troubleshooting thermal problems. I disconnected the mike cord, put the mike on the table, and slowly rotated it on its hang-up button while spraying the seam with freeze spray until the seam turned frosty white. At that point, I picked the mike up in my hand and gave it a few sharp whacks along the seam with a screwdriver handle; it popped open like an egg. I fixed the problem inside and a few drops of instant glue have sealed it back up, good as new.

Some unrepairable microphones aren't sealed around their entire perimeter, but instead have half a dozen plastic posts and sockets further inside. The freeze spray trick won't reach the posts, but putting the mike into the freezer still seems to works fine.

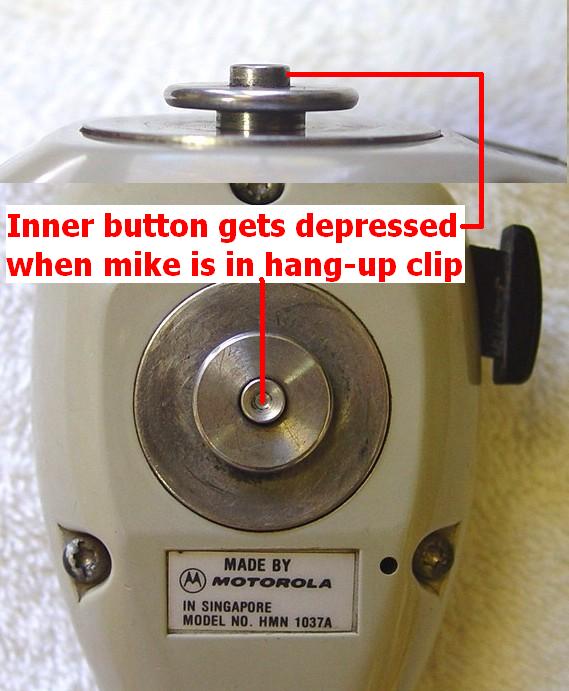

Secondary Button:

Some microphones have a smaller spring-loaded plunger or button in the middle of the normal hang-up button. When this is depressed, it closes a switch inside the mike, which connects the hang-up line to ground. No grounded or conductive hang-up clip is required, but the clip must have some means of pushing the plunger in when the mike is inserted into it. Some clips have springs inside them, like the ones shown above, but cheaper ones could have just a U-shaped opening that the button hangs on; these may not depress the inner button. Most of the DTMF (Dual Tone Multi Frequency) microphones use this style, and this is one of those full-size DTMF hand mikes.

Microphone Hang-Up Box:

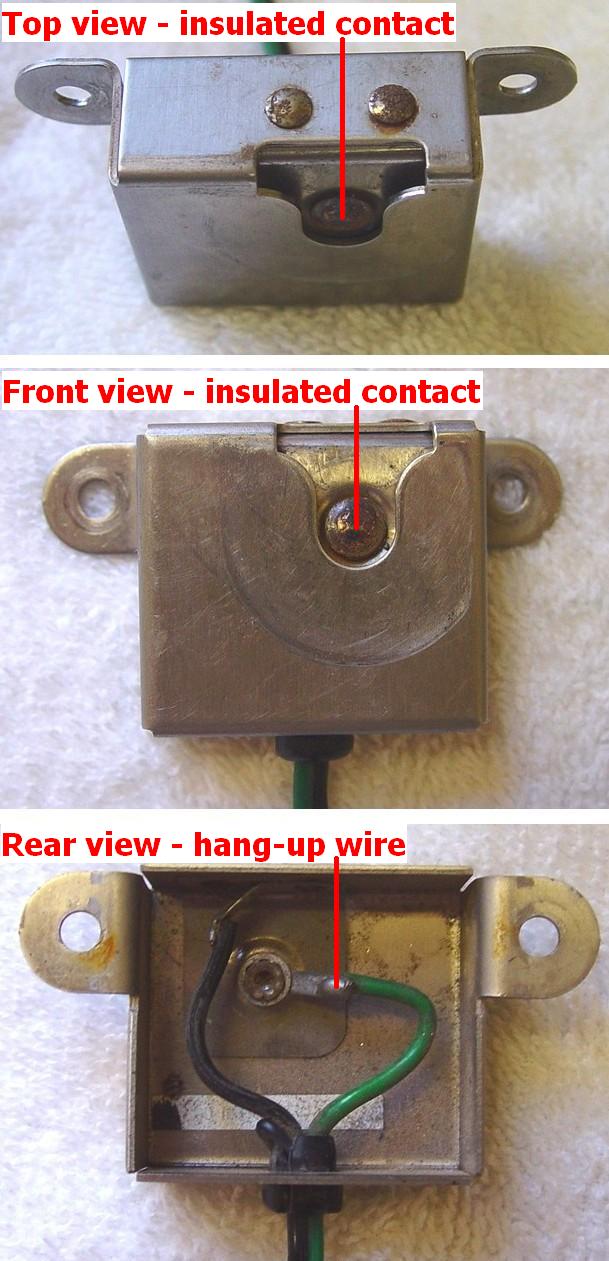

Some of the older mobile radios (Motrac and MICOR) didn't have a hang-up wire in the microphone cable, or used a round four-pin connector that had no provision for this feature. Instead, they used a unique hang-up box, rather than a simple clip, to hold the microphone when not in use. These have a ground wire and an insulated signal wire that get connected to the control head to activate the hang-up feature of the radio. When a metal microphone hang-up button is placed into the hang-up box, the insulated hang-up line is connected to the grounded box and the receiver will activate its tone-coded squelch.

The version shown in the photo below was frequently found in coastal areas, and more so in shipboard installations... the sealed contacts inside the microswitch housing didn't corrode from the atmosphere and provided more reliability than the ones that used open-air-contacts as part of the circuit. The wires are hiding the "C" label on the leftmost switch pin (C for "Common"), and the "NC" on the rightmost pin (for "Normally Closed"). Photo by WA6ILQ.

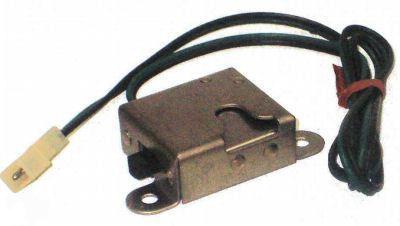

Some hang-up boxes also have a slide switch on the right side of the above photos and wired in series with the switching mechanism. The switch allows you to activate carrier squelch without lifting the microphone out of the hang-up mechanism in the box. The MICOR radio series used that type of box, as the mobile control head didn't have a receiver "PL" switch. Shipping that style of hang-up box as part of the radio installation kit provided a user-accessible monitor switch. The photo below shows a TLN4416A hangup box for a MICOR radio. Photo supplied by WA6ILQ.

There were hybrid radios that used instant-heating tubes in the transmitter and used the switching function in the hang-up box to turn the fast-heating transmitter filaments on when the mike was taken out of the clip. These models were not very popular as many drivers left the microphone on the seat; therefore the tubes were warm full-time and had a short life.

The hang-up box would be wired to the radio or its control head. There were also some boxes that had microphone jacks and cords attached them. You plugged the mike into the hang-up box and plugged the hang-up box into the mike jack on the radio.

There were some telephone-style handsets, with PTT buttons in the "grip" area, used on some full-duplex applications or where some privacy was desired. These had a hang-up "cup" mounted on a vertical surface, into which the earpiece part of the handset could be placed. The hangup switch in the cup could be used to turn the radio on or off or do any other function required - a common one was switching over from a speaker to the handset earpiece when the handset was lifted from the cup.

Desk Microphones:

Even though these do not belong in an article about hand mikes, it makes sense to say something about them. Desk mikes sit on the desk and don't have a hang-up button on the back. Many have two pushbuttons on the front: one labeled "Transmit" which grounds the Push To Talk (PTT) line (and un-grounds the Monitor line for reasons known only to Motorola), and one labeled "Monitor" which un-grounds the hang-up line. There were some that did not have the Monitor button, or had some other push-button switch added by a clever technician. Of course, the newer politically-correct mikes have some kind of internationally recognized graphical symbols for these two functions, in place of the spelled-out words.

Bypassing the Hang-up Function:

For amateur repeater users, you usually do not need to listen on the frequency in carrier squelch mode before transmitting, because you'll hear the repeater if it's active. This does not mean you shouldn't listen first, because there could be activity on the output frequency with a different CTCSS or DCS or none at all. Most users modify the radio or microphone to keep the hang-up line permanently grounded, especially on radios that have a separate Monitor button on the front panel to put the receiver into carrier squelch mode. Shorting the appropriate wires on the front panel's MIC jack is often easy to do. An alternative is to open the microphone (if possible) and add a jumper from the hang-up wire to ground. Note that some units (such as the HMN1056 series shown above) are hermetically sealed and can NOT be opened up or closed again without destroying the case. If you don't see any screws to give you access to the insides, don't try to open it. Some of these mikes have removable cords; if so, repair efforts are basically limited to replacing the cord or the entire mike assembly.

Often, hang-up boxes in taxi-cabs were seen with nickels shoved into the slot, to keep the receiver tone-squelch activated all the time, thus eliminating all that undesired chatter on the shared frequency. The microphone then just sat loose on the seat.

Acknowledgements and Credits:

I tried to be as generic as possible with the terms used to describe the various signals and microphones.

MaxTrac, Radius, GM300, GTX, Motrac, MICOR, and other radio models are trademarks of Motorola, Inc.

Mike WA6ILQ provided the photograph of the microswitch-version hang-up box. All other photos were taken by the author.

X-ACTO is a trademark of Elmer's Products, Inc.

Contact Information:

The author can be contacted at: his-callsign [ at ] comcast [ dot ] net.

Back to the top of the page

This page originally posted on Wednesday 15-Nov-2006

Photographs (except where noted), article text, and hand-coded HTML © Copyright 2006 by Robert W. Meister WA1MIK.

This web page, this web site, the information presented in and on its pages and in these modifications and conversions is © Copyrighted 1995 and (date of last update) by Kevin Custer W3KKC and multiple originating authors. All Rights Reserved, including that of paper and web publication elsewhere.